Capabilities

Allied Technology, Inc. partners with customers to turn complex product designs into reality. With engineering and product design expertise, our team works closely with customers to ensure that we produce the right parts at the right price. From prototyping to production, ATI strives to meet customers’ unique needs and add value to customer’s supply chain.

High Quality that You Can Trust

Quality is the highest priority at Allied Technology Inc.. All of our automotive projects incorporate the PPAP system to ensure we deliver products with the highest quality. We understand that trust is earned, so we welcome all confirmed customers to arrange visits to our overseas plants to validate that we use the highest standards in every aspect of our production operation.

Expertise and Capabilities

For more than 20 years, our ISO/TS certified factories use state-of-the-art machines to consistently produce durable parts ranging in size from 0.05 lbs to 250 lbs with tight tolerances in plastic and metals, including Aluminum, Iron, Steel, and Zinc. Utilizing different manufacturing processes, and sometimes a mixture of several, we supply parts for leading OEMs and ODMs to build vehicles and products that millions of Americans drive and use every day.

Variations:

✓ High Pressure Die Casting

✓ Low Pressure Die Casting

✓ Squeeze Casting

Machine Size: 280 to 1000 tons

Part Size: Up to 15 lbs

Tolerance: Meet customer’s requirement

Capacity: 35,000 lbs per shift

Variations:

✓ High Pressure Die Casting

✓ Low Pressure Die Casting

✓ Squeeze Casting

Machine Size: 50 to 240 tons

Part Size: Up to 8.8 lbs

Tolerance: Meet customer’s requirement

Capacity: 200,000 pcs per shift

Metals for Sand Casting:

✓ Iron

✓ Stainless Steel

✓ Carbon Steel

Automated Machines for:

✓ Coremaking

✓ Sand Processing

✓ Molding

✓ Melting

✓ Pouring

Molding Template Size: Up to 600*700

Part Size: Up to 50 lbs

Tolerance: ±0.01 mm

Capacity: 60 ton per shift

Machine Type:

✓ Hammers

✓ Ring Mills

✓ Presses

Machine Size: 160 to 6300 tons

Part Size: Up to 250 lbs

Tolerance: ±0.2 mm

Capacity: 60,000 lbs per shift

Part Size: 1/8″ to 2″

Tolerance: Within ±0.005″

Capacity: 500,000 pcs per shif

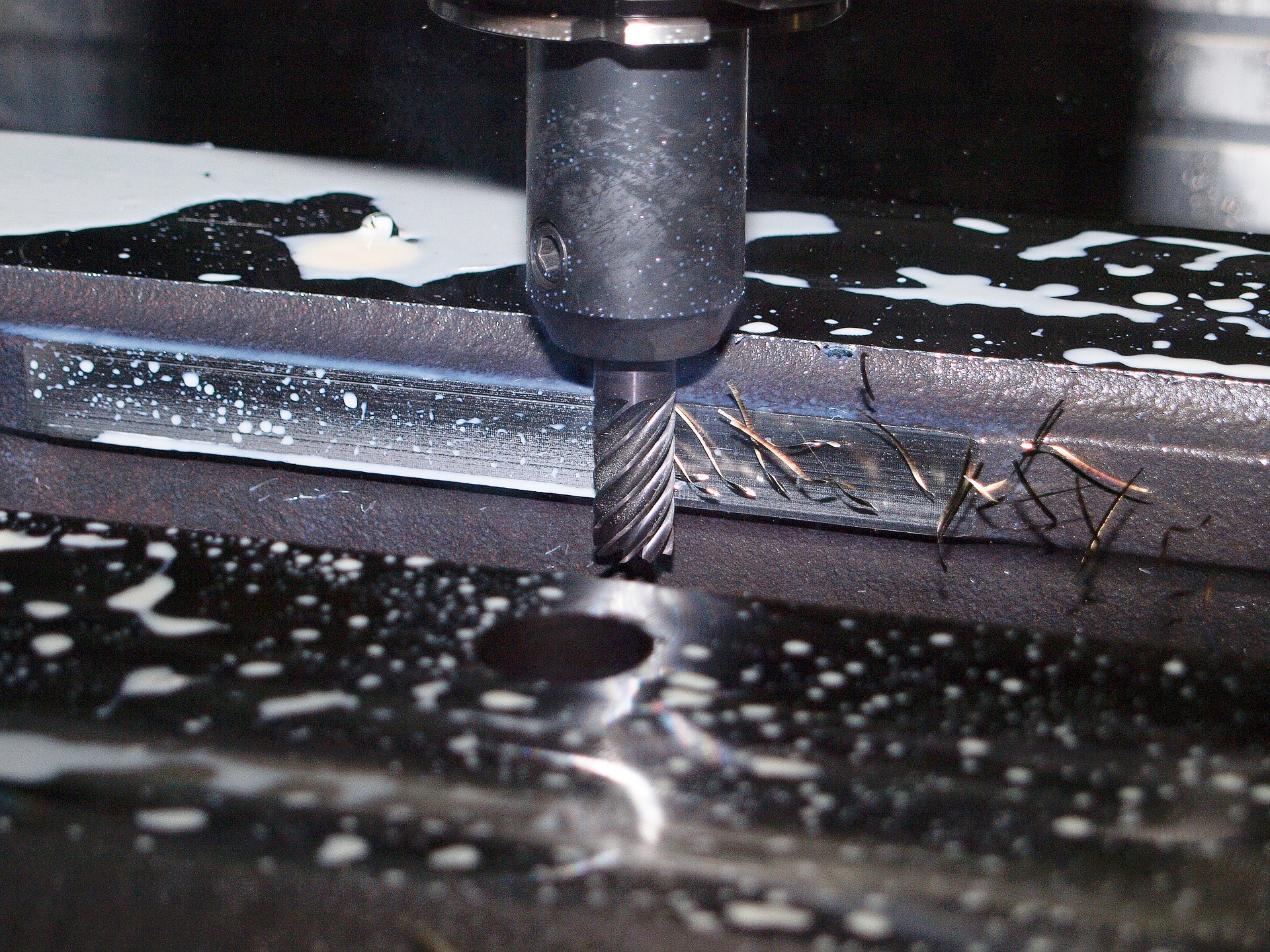

Variations:

✓ Mechanical Cutting

✓ Beam Cutting

Machine Types:

✓ Milling Machines with up to 5 axes

✓ Lathes with 3+2 axes

✓ Laser, Waterjet, and Plasma Cutters

with 3 axes on 5″ by 10″ tables

Part Size: 3/16″ to 2 1/4″ in length, up to

6″ in thickness

Tolerance: Meet customer’s requirement

Capacity: 400,000 pcs per shift

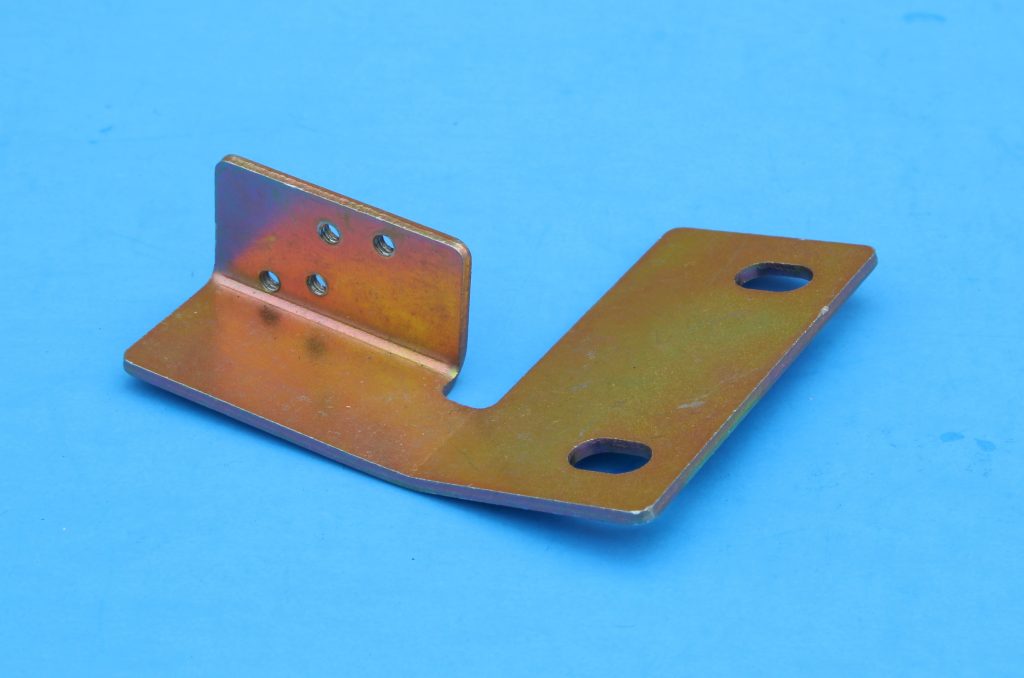

Variations:

✓ Punching

✓ Blanking

✓ Bending

✓ Coining

Press Size: 550 to 3,000 tons

Part Size: Up to 20 lbs

Tolerance: Meet customer’s

requirement

Capacity: 250,000 pcs per shift

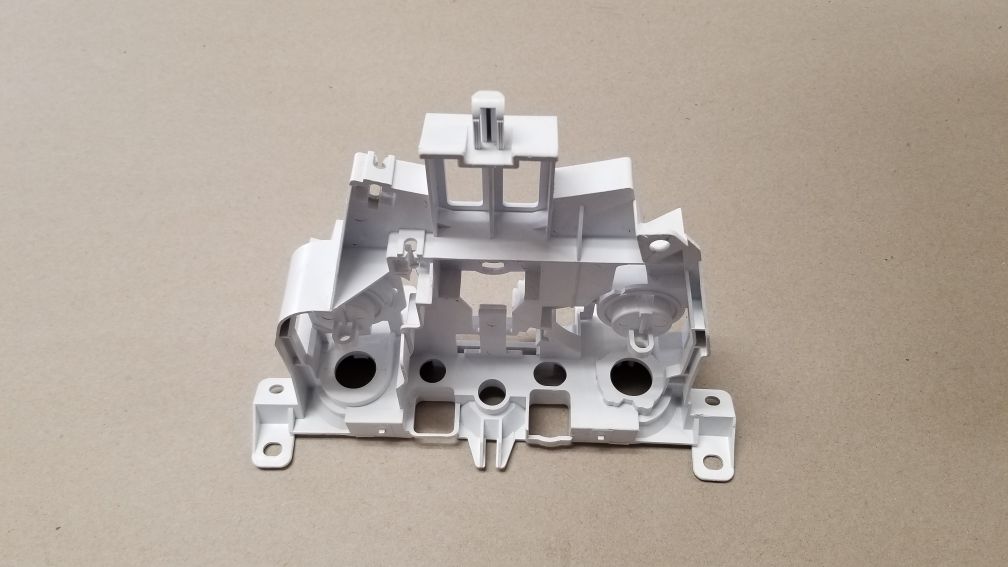

Variations:

✓ Injection Molding

✓ Extrusion Molding

Machine Sizes: 100 g to 5000 g

Part Size: Up to 60*110 cm

Tolerance: Meet customer’s

requirement

Capacity: 88,000 lbs per shift